Leveraging Laboratory Hotplates for Sustainable Science Practices

Laboratories play a pivotal role in advancing knowledge across various fields, yet their operations can often have a substantial environmental impact. From energy consumption to waste generation, the scientific community recognizes the urgency of adopting sustainable practices. Laboratory hotplates emerge as a beacon of eco-consciousness, offering a solution that combines efficiency with environmental stewardship. This guide delves into the transformative potential of laboratory hotplates in fostering sustainability within scientific endeavors.

Understanding Laboratory Hotplates:

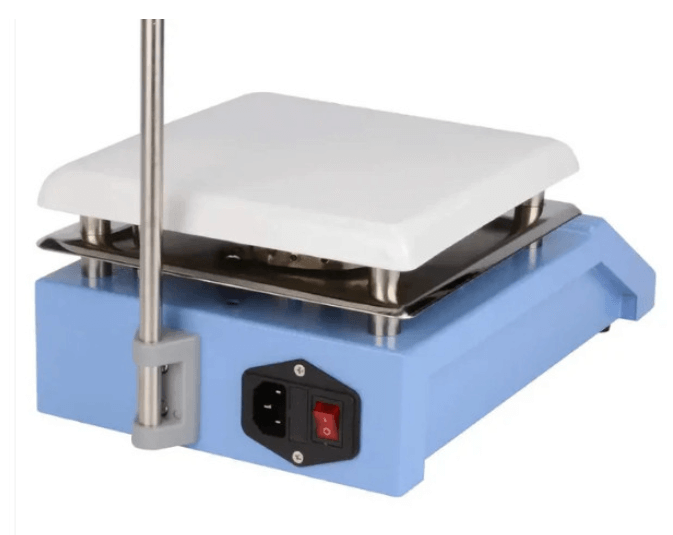

Laboratory hotplate are indispensable tools in research laboratories, providing a reliable means of heating substances for a myriad of experiments. These devices consist of a heating surface, typically made of ceramic or metal, which is heated via electricity or gas. Precise temperature control and uniform heating make hotplates essential for various applications, including chemical reactions, sample preparation, and sterilization processes.

The Environmental Impact of Traditional Heating Methods:

Traditional heating methods, such as open flames and oil baths, are not only inefficient but also pose significant environmental hazards. Open flames release harmful pollutants into the atmosphere, contributing to air pollution and posing safety risks in laboratory settings. Oil baths, commonly used for high-temperature applications, require large quantities of energy and produce waste oil that must be disposed of responsibly. These practices underscore the urgent need for sustainable alternatives in laboratory heating.

How Laboratory Hotplates Promote Sustainability:

Laboratory hotplates offer a sustainable alternative to traditional heating methods by minimizing energy consumption and reducing environmental pollutants. Their efficient design ensures optimal heat transfer, resulting in lower energy requirements and reduced operating costs. Moreover, hotplates eliminate the need for fossil fuels and other non-renewable resources, aligning with the principles of sustainability. By investing in laboratory hotplates, laboratories can mitigate their environmental impact while enhancing operational efficiency.

Applications of Laboratory Hotplates in Green Chemistry:

The principles of green chemistry emphasize the development of environmentally benign processes and products. Laboratory hotplates play a pivotal role in advancing green chemistry initiatives by enabling precise temperature control and facilitating sustainable synthesis routes. From solvent-free reactions to catalytic conversions, hotplates empower researchers to explore innovative solutions that minimize waste and maximize efficiency. By integrating hotplates into green chemistry workflows, laboratories can accelerate the transition towards more sustainable practices.

Innovations in Energy-Efficient Hotplate Design:

Advancements in hotplate technology have led to the development of energy-efficient models that further enhance sustainability. Features such as insulated heating surfaces, programmable temperature settings, and automatic shut-off mechanisms optimize energy utilization and reduce environmental impact. Manufacturers are increasingly prioritizing eco-friendly materials and manufacturing processes to minimize carbon footprint throughout the product lifecycle. These innovations underscore the commitment of the scientific community to sustainability-driven innovation.

Read also: Navigating the Maze: Legal Considerations in UK Property Transactions

Ensuring Safety and Compliance:

While laboratory hotplates offer numerous benefits, safety and regulatory compliance remain paramount. Proper installation, maintenance, and usage protocols are essential to mitigate risks associated with hotplate operation. Laboratories must adhere to industry standards and guidelines to ensure the safety of personnel and the integrity of experimental outcomes. By prioritizing safety and compliance, laboratories can harness the full potential of laboratory hotplates while upholding ethical and environmental responsibilities.

FAQs:

How do laboratory hotplates contribute to energy conservation?

- Laboratory hotplates utilize efficient heating mechanisms and precise temperature control to minimize energy consumption during experiments, thereby reducing overall energy usage in laboratory settings.

Are laboratory hotplates suitable for green chemistry applications?

- Yes, laboratory hotplates play a crucial role in green chemistry initiatives by enabling sustainable synthesis routes, minimizing waste generation, and facilitating environmentally benign processes.

What safety precautions should laboratories take when using hotplates?

- Laboratories should ensure proper installation, regular maintenance, and adherence to safety protocols when using hotplates. Additionally, personnel should receive adequate training on hotplate operation and safety procedures.

How can laboratories ensure regulatory compliance when using hotplates?

- Laboratories should familiarize themselves with industry standards and guidelines governing hotplate usage, including safety regulations and environmental requirements. Regular audits and inspections can help ensure compliance with regulatory standards.

What are some key features to consider when selecting a laboratory hotplate?

- When selecting a laboratory hotplate, laboratories should consider factors such as temperature range, heating surface material, energy efficiency, safety features, and compatibility with experimental requirements. Consulting with knowledgeable suppliers can help identify the most suitable hotplate for specific applications.

Future Trends in Hotplate Technology:

- Integration with Smart Lab Systems: Hotplates equipped with IoT capabilities and data logging functionalities enable remote monitoring and control, enhancing workflow automation and data management.

- Renewable Energy Integration: The incorporation of renewable energy sources such as solar and wind power into hotplate design holds promise for further reducing the carbon footprint of laboratory operations.

- Advances in Heating Technology: Ongoing research efforts aim to develop novel heating technologies with improved energy efficiency, faster heating rates, and enhanced temperature stability, paving the way for next-generation hotplates.

- Sustainable Materials Innovation: Manufacturers are exploring sustainable materials such as recycled plastics and bio-based polymers for hotplate construction, reducing reliance on virgin resources and minimizing environmental impact.

- Collaborative Initiatives: Industry collaborations and interdisciplinary research endeavors are driving innovation in hotplate technology, fostering cross-sectoral partnerships to address sustainability challenges in laboratory heating.

Conclusion:

Laboratory hotplates embody the intersection of scientific innovation and environmental stewardship, offering a sustainable solution for heating applications in research laboratories. As laboratories worldwide prioritize sustainability in their operations, hotplates emerge as indispensable tools for advancing green chemistry, reducing energy consumption, and minimizing environmental impact. By leveraging the efficiency and versatility of hotplates, laboratories can embrace sustainable science practices while achieving their research objectives. certifiedmtp.com remains at the forefront of providing high-quality laboratory equipment, including cutting-edge hotplates, to support the scientific community in its journey toward environmental sustainability.